Metal Injection Moldings

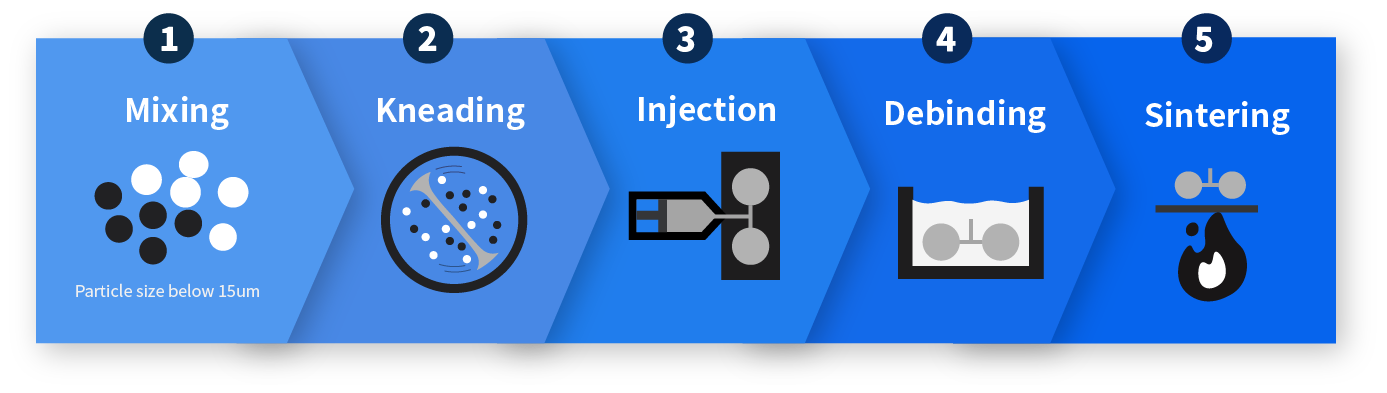

Process

Mixing ⇨ Kneading ⇨ Injection ⇨ Debinding ⇨ Sintering

Material selection and mechanical properties

| Matal Types |

Density(g/cm3) |

Tensile Strength(MPa) |

Elongation(%) |

Hardness |

Magnetic Respons |

| 316L |

>7.5 |

500 |

40 |

HRB 50~60 |

N/A |

| 17-4PH(As-Sintered) |

7.5 |

900 |

6 |

HRB 23~26 |

Low |

| 17-4PH(Heat-Treated) |

7.5 |

1190 |

5 |

HRB 33~40 |

Low |

| F75 |

>7.5 |

728 |

23 |

HRB 29~26 |

N/A |

| 4605(As-Sintered) |

7.5 |

440 |

15 |

HRB 70~80 |

Average |

| 4605(Heat-Treated) |

7.5 |

1655 |

2 |

HRB 48~52 |

Average |

| 4605 Modified |

7.5 |

1800 |

5 |

HRB 48~53 |

Average |

| 1010 |

7.6 |

300 |

12 |

HRB 40 |

Good |

| SKD-11(D2)(Heat-Treated) |

7.7 |

800 |

<1 |

HRB 55~62 |

Average |

| 420 |

7.2 |

1200 |

1~2 |

HRB 46~50 |

Average |

| 440C |

7.6 |

800 |

<1 |

HRB 50~57 |

Average |

| W-Ni-Cu |

17.8 |

780 |

3 |

HRB 28~32 |

Average |

| W-Ni-Fe |

18.0 |

950 |

8-9 |

HRB 28~32 |

Average |